Day 1 :

Keynote Forum

Mosongo Moukwa

PolyOne Designed Structures and Solutions LLC, USA

Keynote: Specialty films and multilayered structured: A review

Time : 10:30-11:15

Biography:

Abstract:

Global specialty and high performance films market is expected to reach $44.59 Bn by 2020, growing at 6.4% from 2014 to 2020, according to Transparency Market Research. Specialty and high-performance films are thin films with unique properties such as high or low heat conductivity, barrier properties, special surface properties, high purity, and mechanical properties. They are films made from various polymers such as polypropylene, polyamide, polyethylene, polyvinyl chloride, polycarbonate, ethylene vinyl alcohol, and polyester. Manufacturers have invested in research and development to create innovative products by developing multilayer films structures, combining low costs, high costs films, nanoparticles, and increased biopolymers. This is an overview of some modern aspects and trends in the development of specialty films and multilayered structures. Multi layered structures have allowed the construction of films with outstanding properties used in some of the toughest applications. They include barrier films, decorative films, and safety and security films. Their applications include food and cosmetics packaging, electronics, automotive and aerospace applications. A number of technical developments have taken place over the recent years to extend the performance of these types of films. Scientists and engineers are developing new materials in order to meet the evolving technical challenges, more stringent specifications, applications in harsher environments, demanding customer’s requirements and evolving environmental legislations. Possibilities are immense. Manufacturers are able to introduce new products with better performance by developing multilayer film structures, combining low cost and high cost films, and in some cases using of biodegradable polymers.

|

|

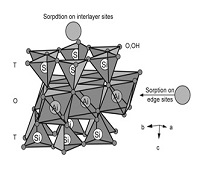

Figure: Structure of montmorillonite (phyllosilicate clay)

Networking & Refreshment Break 11:15-11:35 @ Foyer

Keynote Forum

Rene Hensel

INM – Leibniz Institute for New Materials, Germany

Keynote: Bio-inspired elastomeric adhesives for novel pick-and-place concepts

Time : 11:35-12:20

Biography:

René Hensel studied Materials Science at the TU Dresden, Germany. He was a fellow of the DFG Research Training Group 1401/2 at the TU Dresden and did his Doctorate at the Leibniz Institute of Polymer Research Dresden (IPF) and the Max Bergmann Center of Biomaterials Dresden (MBC). He was honored with the International Bionic Award 2014 from VDI for his PhD thesis on free-standing polymer membranes for omniphobic surface coatings. Since 2014, he has been the Deputy Head of the Program Division Functional Microstructures at Leibniz Institute for New Materials Saarbrücken, Germany.

Abstract:

Strong, but reversible adhesion to diverse counter surfaces has attracted the attention of several research groups worldwide. Inspired from concepts found in biology, micropatterned dry adhesives were identified as promising candidates, particularly due to their potential for the development of novel pick-and-place concepts. Whereas, fundamental principles and design guidelines of such adhesives to handle objects with smooth surfaces have already been reported in several reports; current developments undergo rapid progress towards applications in non-ideal conditions. Here, we will discuss the impact of surface roughness among other scenarios such as elevated operating temperatures and a reduced air pressure. As an example, surface roughness substantially reduces contact area; however, we found that an appropriate design of the surface pattern can lead to acceptable adhesion performances. By an intense interplay between experiment and theory, we studied a new composite design that maintains the structural concept of contact splitting in combination with soft materials to overcome critical issues in contact formation such as the strain energy penalty. Our developments demonstrate practical solutions for current limitations and might pave the way for emerging applications of bio-inspired pick-and-place systems in the real world.

Keynote Forum

Dukjoon Kim

Sungkyunkwan University Suwon, Korea

Keynote: Proton exchange membranes prepared from crosslinked and multi-block copolymers based on poly (arylene ether ketone)

Time : 12:20-13:05

Biography:

Dukjoon Kim has completed his PhD from Purdue University and Postdoctoral studies from Lehigh University. He was the Executive Director of Korea Polymer Society and now the Director of BK 21 Program in SKKU. He has published more than 170 papers in reputed journals on functional polymer material files.

Abstract:

Sulfonated poly(arylene ether ketone)s (SPAEKs) are for application of fuel cell electrolyte membranes. The chemical structure of the polymers synthesized is identified using 1H - and 19F- nuclear magnetic resonance spectroscopy, attenuated total reflection fourier transform infrared spectroscopy. Sulfonated mesoporous benzene-silica (SMBS) hygroscopic conductors are embedded in the membranes to lessen their dehydration in the low humid environment. The effects of sulfonation degree (SD) and hygroscopic conductors on the membranes properties are analyzed. The prepared SPAEK membranes are thermally stable up to 250oC without any chemical degradation. While the SPAEK membranes containing hygroscopic proton conductors exhibit superior conductivity to that of Nafion®117, those showed lower methanol permeability. Although the water uptake of the composite membranes is higher than that of the pristine membranes, no mechanical failure is observed. In the synthesis of SPAEK, the development of distinguished hydrophobic-hydrophilic phase separation is confirmed by small-angle X-ray scattering spectroscopy. SPAEK copolymer membranes show excellent oxidation stability.

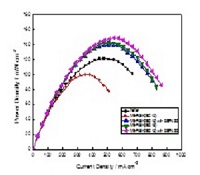

Figure: Cell performance of SPAEK membranes in comparison with Nafi on

Lunch Break 13:05-14:00 @ Athens

- Polymer Science- The Next Generation | Polymer Material Science and Engineering | Polymer Physics

Location: London

Chair

Linyong Song

University of Kansas, USA

Session Introduction

Linyong Song

University of Kansas, USA

Title: Self-strengthening dental adhesive: Mechanism and long-term behaviour

Time : 14:00-14:35

Biography:

Linyong Song is Ph.D. is in Polymer Chemistry from the University of Science and Technology of China. He received his B.S. from Tianjin University in Polymer Engineering. His main area of interest is Biomaterials, Interfacial Polymerization, Synthesis of Functional Monomers, Micro/Nano Structure Materials

Abstract:

The degradation of methacrylate-based dental adhesives via chemical and enzymatic hydrolysis leads to destruction of the integrity of the dentin/adhesive interface, loss of bond strength and failure of the composite restoration. Self-strengthening methacrylate-based adhesive systems were developed by introducing visible-light irradiation induced (photoacid-induced) sol-gel reaction. The self-strengthening mechanism and mechanical properties of copolymers were investigated by real-time Fourier transform infrared spectroscopy (FTIR) and dynamic mechanical analyzer (DMA), respectively. HPLC was used to determine cumulative amount of leached species. Time-temperature superposition (TTS) was employed to predict the long-term performance. The results indicated that with the incorporation of organosilane components, self-strengthening adhesives showed 1) significantly reduced leachable species (HEMA and BisGMA); 2) gradual increase in mechanical properties under wet conditions (neutral or acidic pH); 3) better long-term behavior predicted by TTS. In conclusion, the mechanical properties of this resin are reminiscent of living organisms such as marine invertebrates. These results provide valuable information for the development of dental adhesives with enhanced durability.

Hitesh R Patel

Ganpat University, India

Title: Formulation and evaluation of oral mucosal casein salt fi lm for the anti-diabetic activity

Time : 14:35-15:10

Biography:

Dr. H R Patel has completed his PhD study from S. K. P. C.P. E. R. Ganpat University (Pharmaceutical science) in Novembwe, 2009. He has worked on research Project in Polymer and Pharmaceutical Sciences funded by Government of India. He has 25 National and Interntional Research paper Publication. His topic of interest is in Formulation and Development of Sustained and Controlled release Drug Delivery System for oral mucosal drug delivery.

Abstract:

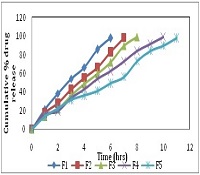

To develop the novel formulation in the era of modern drug delivery system with their biodegradable drug delivery, we have prepared the oral mucoadhesive formulation from the protein material like salts of casein. It has shown good compatibility and desire drug release with no side effect. Different concentration of sodium caseinate, calcium caseinate was added in a polymer mixture to prepare the films were evaluated for physical parameters. In-vitro diffusion studies of the patches were performed and the samples were analyzed by HPLC method. The cumulative percent drug release was plotted against time and the slope of the linear portion of the curve estimated by first order, korsemeyer’s equation and higuchi kinetics. The IR spectral data and DSC studies showed that there was no interaction between drug and utilized polymers. All the films were found to be flexible, smooth surface texture, transparent and uniform in weight and thickness. Among all formulations, formulations F4 shows 93.24% drug release at the end of 12 hrs. The films prepared from casein salt have shown a diffusion controlled release. Hence these formulations were further subjected for in-situ diffusion studies and in-vitro - in-situ correlation was carried out. Different kinetic models were used for the determination of release pattern. The present investigation resulted in the development of protein film for the drug delivery with good bioadhesive strength and further there is a scope to conduct the in-vivo diffusion studies by using various experimental animal models and correlate the in-vitro- in-vivo diffusion parameters.

Figure: In-vitro drug release profile of insulin film

Girish N. Patel

Ganpat University, India

Title: Design and development of bilayer gastroretentive tablet containing metformin HCl and glipizide for the treatment of type II diabetes

Time : 15:10-15:45

Biography:

Dr. Girish N Patel is a Ph.D., M. Pharm and he completed his Ph.D from Hemchandracharya North Gujarat University, patan, Gujarat, India. His area of interest mostly lies in the field of Polymer Technology

Abstract:

The aim of the present research work is to develop and optimize a bilayer antidiabetic floating matrix tablet containing Metformin HCI (MET) as sustain release in one layer, using different grades of hydroxy propyl methyl cellulose (HPMC) by direct compression method, and glipizide as immediate release from the remaining layer. Immediate action of glipizide will be helpful to control excess sugar, which will be maintained by metformin action later on. Thus, the developed single tablet will be sufficient instead of three to four tablets of both drugs per day, and it will also increase patient compliance and therapeutic efficacy. The formulations of immediate release layer were prepared by using various super disintegrants i.e. crossprovidone, sodium starch glycolate, and croscarmellose sodium by direct compression technique. 32 full factorial design was used to optimize sustain release formulations of Metformin HCl. The ratio of polymer blend (X1) and content of gas generating agents blend (X2) were chosen as independent variables. The tablets were evaluated for in-vitro dissolution profile, in-vitro buoyancy studies, comparison of dissolution profiles, kinetic modeling and drug release mechanism. Different super disintegrants were used to prepared immediate release tablets of GPZ. Among these SSG (5%) give good disintegration and the GPZ was completely released within 1 hr. Among the different grades of HPMC investigated, significant difference in the resulting MET release profiles from the SR layer of tablets was found. This indicated that the viscosity of the polymer affects the drug release rate when the drug is water-soluble and the dose is high. The results conclude that bilayer gastro retentive tablet of Metformin HCl and Glipizide shows desirable release profile, good floating, and sustained effect in stomach. There is a further scope to conduct the in-vivo studies by using various experimental animal models and correlate the in-vitro- in-vivo correlation.

Kossi Nicolas ASSIGBE

University Grenoble Alpes, France

Title: Thermo-mechanical characterizations of polymers for microelectronics applications

Time : 15:45-16:10

Biography:

Kossi Nicolas ASSIGBE is an young researcher of 24 years born in TOGO with a diploma of mechanical design engineer (TOGO, 2014) and a master research in materials mechanics (France, 2015). Passionate about understanding the behavior of materials, I am now working on the temperature instability of the thermomechanical properties of polymer films used in microelectronics. I am a PhD student based at CEA (Commissariat of Atomic Energy and Alternative Energies) and SIMaP (Laboratory of Science and Engineering of Materials and Processes).

Abstract:

In microelectronics, 3D integration involves stacking different electronic components on a substrate. During the various steps of the process, bonding is carried out using several types of polymeric materials. The use of these materials can be advantageous: they are generally carried out at deposition temperatures lower than those of the other integrated materials and it is possible to integrate them in liquid form under components and then crosslink them. They also have the advantage of offering various mechanical properties, which make it possible both to protect certain components but also to produce more flexible layers if necessary. Conversely, they exhibit high coefficients of thermal expansion (CTE), which can lead to problems of reliability of the components. Moreover, their mechanical properties can change over time when the crosslinking annealing has not been optimized. Thus, their characteristics may be unstable when used in manufacturing processes. The aim of this work is to develop a method for studying the evolution of thermomechanical properties of polymers used in manufacturing processes as a function of temperature. In the first part of this work we carried out experimental measurements using a measuring equipment (k-SA MOS Thermoscan) to measure the evolution of the curvature of deposit materials on substrate. We carried out this study for different types of polymer materials deposited on a silicon substrate. The objective is to measure their curvature evolution for different temperature. The equipment is equipped with an in-situ furnace which allows us to heat the plate with a controlled temperature ramp from ambient temperature up to 1000 ° C. In the second part we have developed an analytical calculation program to solve static equilibrium equations during cooling or heat treatment taking into account thermo-elastic properties variation. From the measurements of curvature variations, an inverse analysis makes it possible to identify the thermo elastic properties of the polymers films. Finite element validation will also be presented.

Networking & Refreshment Break 16:10-16:30 @ Foyer

Yingdi Yan

Maria Curie Sklodowska University, Poland

Title: Fabrication of cell membrane mimic phospholipid polymer brush surface and its protein resisitant property

Time : 16:30-16:55

Biography:

Yingdi Yan obtained her master degree in Zhejiang University in China and her research topic is “The micro-nano structure design of novel superhydrophobic coatings and their anti-icing& icephobic properties”. Now she is conducting her PhD study at department of physical chemistry- interfacial phenomena, faculty of chemistry, Maria Curie Sklodowska University with the support of CoWet (Complex Wetting) project from Marie Curie Initial Training Network (Project number 607861). The subject is “Wetting and electro-kinetic properties of solid supported lipid layers”. Three topics are involved: 1. DPPC mono-/bi- layer deposited on Ti-6Al-4V via spreading and LB/LS method and investigation on their wettability and biostability, 2. DPPC liposome adsorption on hydroxylappatite, and the electrokinetic properties and wettability of DPPC layers in the presence of enzymes. 3. Cell membrane mimic phospholipid polymer brush preparation and its anti-fouling property.

Abstract:

As a promising method to obtain well designed adaptive biointerfaces, polymer brush has aroused broad interest worldwide. Surface initiated polymerization (SIP) has been proved an effective way to obtain thick and dense polymer brush. The newly reported Cu (0) mediated controlled radical polymerization (CuCRP) showed advantanges with repect to lack of toxic halide, tolenrence to oxygen, little reaction solution consumption and reusage of copper plate as a catalyst. To facilitate the biocompatibility and suppress unfavourable protein adsorption, 2-methacryloyloxyethyl phosphorylcholine (MPC) was used, the structure of which is designed to mimic the the main component of biological cell membranes, phospholipid. This is the first time to report PMPC brush fabrication with SI-CuCRP and investigate the mechanism of protain resistance from the viewpoint of surface free enery analysis.

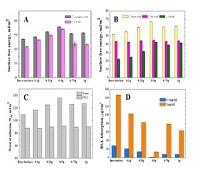

The polymerization process was tracked by XPS and static contact angle measurement and the surface topography was ananlyzed by optical profilometer and AFM. The growth rate of the polymer brush is extremely high and the film thickness could be adjusted by reaction variability, e.g. monomer concentration and reaction time. The graft density was calculated with the help of ellipsometry measurement in dry (0% humidity) and wet (>96%) conditions and its dependence on the monomer concentration and swelling ratio was found. The hydrophilicity was analyzed by surface free energy and its components calculation based on LWAB and CAH approaches and its relationship with protein resistant property was established. The total surface free energy was augmented compared with the untreated surface which are mainly attributed to the polar components increase because the London dispersion interactions are almost the same in spite of the polymer brush modification. An optimal thickness of PMPC implies protein resistance related to surface conformation. Probably self-condensation or charged segments being packed inside the film led to weak surface hydration.

Figure: (A) Apparant total surface free energy of PMPC grafted surfaces with different monomer concentration. (B) Individule CAH surface free energy of PMPC grafted surfaces calculated from water, diiodomethane contact angles and the electron-donor parameter gs- calculated from LWAB method. (C) Work of adhesion of water and diiodomethane to PMPC grafted surfaces; (D) BSA adsorption on the bare surface and PMPC modified surface.

Saad R Ahmed

University of Missouri, Columbia

Title: Experimental and simulation study of tension properties of unsaturated reinforced polyester at low temperature

Time : 16:55-17:20

Biography:

Saad Ahmed is a PhD candidates in Mechanical and Aerospace Engineering school in University of Missouri Columbia.. Over 7 years, experience of working on a milestone driven as well as economically competitive projects for the development and commercialization of innovative materials. Extensive knowledge and experience in the material characterization and specifications measurement techniques for the industrial materials of manufacturing to provide optimized design. He hands on experience on the experimental and computational fluid dynamics. Creative individual with excellent problem solving skills and practical sense of connecting science and technology.

Abstract:

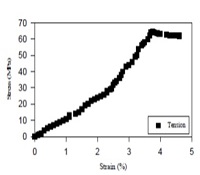

The cryogenic properties of polymers have received great attention with new developments in military and petrochemical processes that require operation at low temperature. This paper presents the evaluation of unsaturated reinforced polyester under static and dynamic loading at extreme temperatures. An environmental chamber was used to test the influence of sub-zero process temperatures on the tensile properties of the specimens. Simulation of tensile properties has be conducted by LS-DYNA and compared with the experimental results. Microstructure examination of the specimens after failure is conducted and evaluated.

Figure: Typical stress versus strain curves in tension and compression for the polyester resin.

Header Haddad

Swinburne University of Technology, Australia

Title: Optimization of thermal and mechanical properties of unsaturated polyester resin as a binder in polymer concrete for manufacturing precision tool machine base

Time : 17:20-17:55

Biography:

Header Haddad has expertise in evaluation and passion in improving the thermosetting polymer for composite materials in manufacturing the base of precision tool machine. His approach is based on application requirements and how to develop new methods to optimize the composite material through polymer and the aggregates of the composite materials. Another applications that Header researched are injection moulding and blow moulding. Headers research is all industrial based in connection with well-known companies such as ANCA.

Abstract:

This study investigates the effect of unsaturated polyester resin chemical composition on the coefficient of thermal expansion, damping properties, flexural strength, tensile strength and hardness. The resin was used as binder in polymer concrete for manufacturing the base of precision tool machine. Resins of various ratios of styrene-ARAPOL and methyl methacrylate (MMA)-ARAPOL were made and curing kinetics were followed using viscosity measurements and exothermic reaction temperature profile. The resins were studied using dynamic mechanical analysis and in house thermal expansion measuring devices. It was found that ARAPOL–MMA (60:40) has the highest damping factor 5.46%, and the thermal expansion coefficient of 7.98×10-5/°C. This composition also has the optimum flexural strength and tensile strength at 128 MPa and 5.86 MPa.

Figure: Coefficient of thermal expansion of MMA and styrene – AROPOL resins.