Mosongo Moukwa

PolyOne Designed Structures and Solutions LLC, USA

Title: Specialty films and multilayered structured: A review

Biography

Biography: Mosongo Moukwa

Abstract

Global specialty and high performance films market is expected to reach $44.59 Bn by 2020, growing at 6.4% from 2014 to 2020, according to Transparency Market Research. Specialty and high-performance films are thin films with unique properties such as high or low heat conductivity, barrier properties, special surface properties, high purity, and mechanical properties. They are films made from various polymers such as polypropylene, polyamide, polyethylene, polyvinyl chloride, polycarbonate, ethylene vinyl alcohol, and polyester. Manufacturers have invested in research and development to create innovative products by developing multilayer films structures, combining low costs, high costs films, nanoparticles, and increased biopolymers. This is an overview of some modern aspects and trends in the development of specialty films and multilayered structures. Multi layered structures have allowed the construction of films with outstanding properties used in some of the toughest applications. They include barrier films, decorative films, and safety and security films. Their applications include food and cosmetics packaging, electronics, automotive and aerospace applications. A number of technical developments have taken place over the recent years to extend the performance of these types of films. Scientists and engineers are developing new materials in order to meet the evolving technical challenges, more stringent specifications, applications in harsher environments, demanding customer’s requirements and evolving environmental legislations. Possibilities are immense. Manufacturers are able to introduce new products with better performance by developing multilayer film structures, combining low cost and high cost films, and in some cases using of biodegradable polymers.

|

|

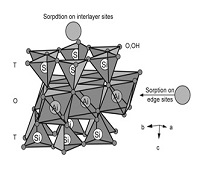

Figure: Structure of montmorillonite (phyllosilicate clay)