Usman Yaqoob

University of Ulsan, Republic of Korea

Title: Synthesis of high dielectric constant fl exible piezoelectric sheet using P(VDF-TrFE)-BTO-rGO composite and its application to energy harvesting

Biography

Biography: Usman Yaqoob

Abstract

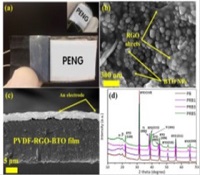

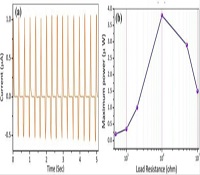

Piezoelectric materials have attracted considerable attention due to their ability to scavenge electrical energy directly from ambient mechanical sources. The energy harvesting from these materials can be a promising way to phase out conventional batteries and power cables. Over the past few decades, considerable efforts have been made to develop a flexible piezoelectric material that possesses high dielectric constant and high breakdown strength by combining polymer-ceramic composites. However, high amount of ceramic filer (>50 vol%.) is required to obtain the maximum dielectric constant (k) from the composite material which can reduce the mechanical flexibility of the composite film. To address this matter, and for further enhancement in k value, a possible solution is to employ a conductive filler. The introduction of conductive filler will not only elevate the dielectric constant by forming several micro-capacitors inside the composite but will also assist in the stabilization of the polar beta (β) phase of the P(VDF-TrFE). The polar β phase of polymer is highly required to obtain maximum energy harvesting properties. Herein, we presents the synthesis and optimization of flexible piezoelectric materials based on poly(vinylidenefluoride)-reduced graphene oxide-barium titanate (PVDF-RGO-BTO) for its application in energy harvesting. To obtain the maximum dielectric constant, different compositions have been prepared by varying the reduced graphene oxide (RGO) contents in the PVDF-BTO nanocomposition. The sample with 5wt% RGO contents (PRB5) has revealed maximum dielectric constant of 170 at 1 kHz. Therefore, has been selected to fabricate the piezoelectric nanogenerator (PENG). The fabricated PENG exhibits maximum open circuit voltage of 4 V(pk-pk) and short-circuit current of 1.5 μA(pk-pk) at an applied force of 2N. Additionally, the maximum output power for the fabricated PENG was recorded around 3.8 μW at 1 MΩ load resistance. It was estimated that fabricated PENG can be a promising energy source for futuristic flexible electronics.